Leave your phone and we will contact you!

Or you can call us yourself:

+7 912 250 57 96

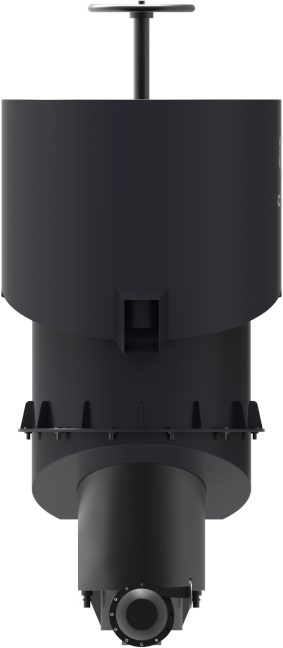

Centrifugal pneumohydraulic flotation machine built by «S.Kat» company

It permits to use high effective flotation of ultrafine mineral particles, which size of up to 1 µm

Flotation

En

+7 912 250-57-96

High specific productivity — 18-20 tons of flotation machine volume during flotation time — 1-1,5 minutes. It's up to 10 times more than it's analogous.

It's according to industrial test data of prototypes of a centrifugal flotation machine that volumes are 1,2m³ and 3,5m³ in comparison with the performance of mechanical and pneumo mechanical machines.

The features of test sample

Volume of «CPFM 03» — 300 litres

Up to 2,5 tons/hour

Productivity

Up to 30 m³/hour

Circulating flow rate

Up to 50 m³/hour

Air Flow

Up to 7,5 m³/hour

Initial pulp capacity

0,15 - 0,2 MPа

Circulation pressure

S:L — 1:3

Solid to liquid proportion of pulp

Simplicity of constructions for repair and maintenance

The new generation of flotation machines has the simplest durable construction and easily removable structural elements that allow it to be repaired and serviced as soon as possible

level regulator of pulp

receiver of froth product

Body

2nd and 3rd stages of aeration

1st stage of aeration

Fragment of the video presentation of the test sample «CPFM 03»

Volume «CPFM 03» — 300 litres

Ekaterinburg, 2019

The use of the CPFM allows to save production space and reduce the flotation fund, reduce operating costs and energy consumption, increase the extraction of useful materials during finely interspersed and difficult ore processing.

It's according to industrial test data of prototypes of a centrifugal flotation machine that volumes are 1,2m³ and 3,5m³ in comparison with the performance of mechanical and pneumo mechanical machines.

"

Сhief enrichment specialist of «S.Kat» company, author of the development «CPFM 03»

Stanislav Orlov

Still have any questions? Ask it to our specialist

Or send a request for a full video presentation «CPFM 03»

+7 912 250 57 96

Send a request

I accepted the policy the processing of personal data. Full text of policy the processing of personal data is located here: https://www.s-kat.com/policy

LLC «S.Кат». All rights reserved.

Policy the processing of personal data.

Policy the processing of personal data.

Contacts

- hello@s-kat.com

- +7 343 226-06-62

Address

- LLC «S.Кат»

620075, Ekaterinburg

Malysheva str. 51,

office 45/08

BC «Vysotsky»